編号 :

ZL-D325(1)

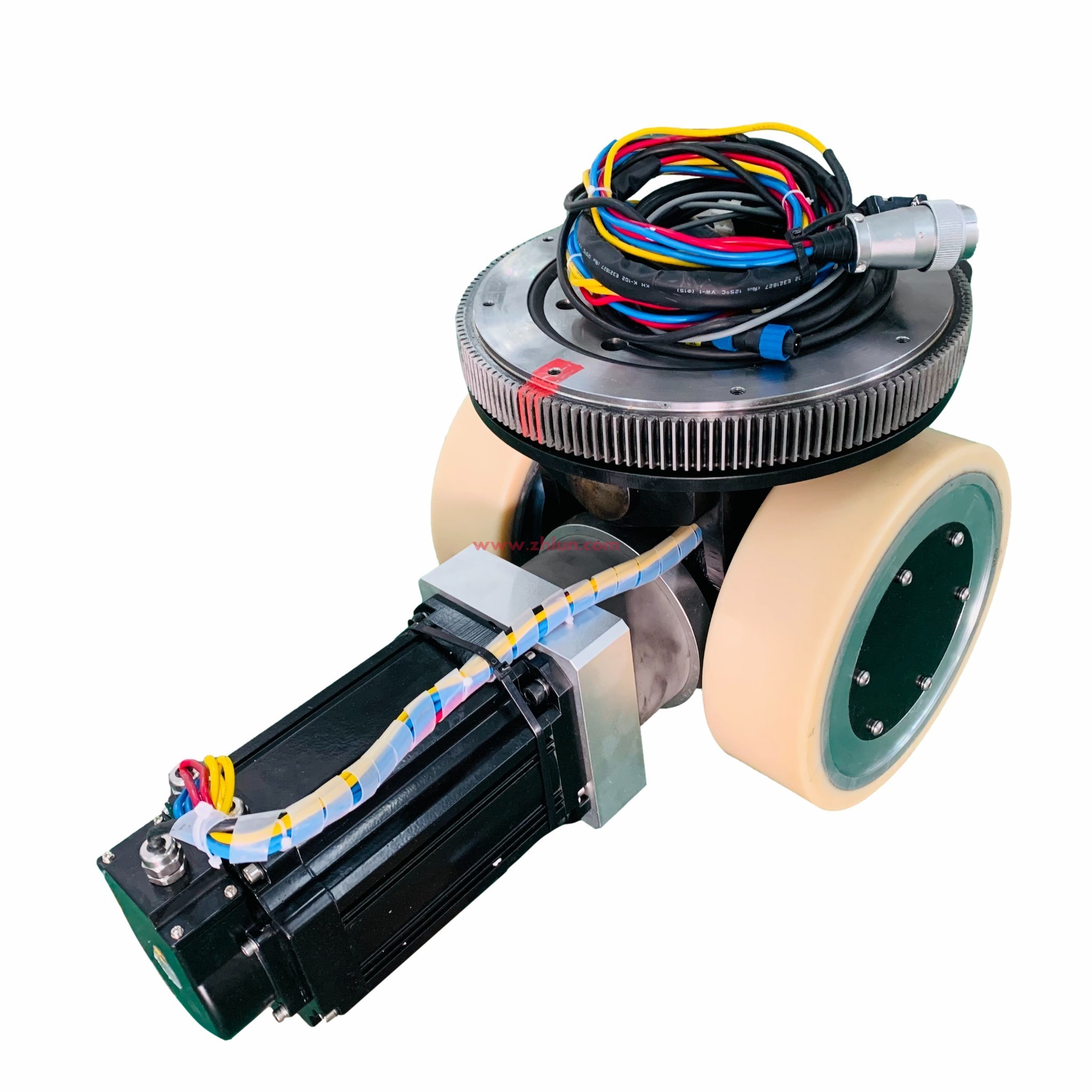

ZL - D325 Differential Drive Steering Wheel: 3 - Ton Load Capacity & Customizable Solutions for AGV Systems

Product number:ZL-D325(1)

隐藏域元素占位

- Product description

-

Discover the Power of ZL - D325 Differential Drive Steering Wheel

In the ever - evolving landscape of industrial automation and material handling, the ZL - D325 differential drive steering wheel stands out as a game - changing solution. As the demand for more efficient, reliable, and adaptable equipment grows, especially in the realm of Automated Guided Vehicles (AGVs), the ZL - D325 is designed to meet and exceed these expectations.

1. Exceptional Load - Bearing CapacityThe ZL - D325 is engineered with a remarkable load - bearing capacity.With a standard rating of 3 tons, it can handle heavy - duty tasks with ease. This high load - bearing ability is crucial in industries such as manufacturing, where large - scale components and products need to be moved. For example, in automotive manufacturing plants, engines and large chassis parts can be transported using AGVs equipped with the ZL - D325. What's more, the load - bearing capacity of the ZL - D325 is customizable. Whether your operation requires a steering wheel that can carry 2 tons or 5 tons, our team can tailor the design to suit your specific needs. This flexibility makes it an ideal choice for a wide range of applications, from tiny workshops to large industrial parks.

2. Innovative Design FeaturesDual - Wheel SurfaceThe dual - wheel surface design of the ZL - D325 is a key feature that enhances its performance. This design distributes the load more evenly, reducing the pressure on each wheel and thus minimizing wear and tear. It also improves the stability of the AGV, ensuring movement even on uneven surfaces. In a warehouse setting, where AGVs need to navigate over various types of flooring, the dual - wheel surface of the ZL - D325 provides the necessary stability to prevent tipping and ensure safe transportation of goods.Equipped with a DifferentialThe inclusion of a differential in the ZL - D325 is another highlight. When an AGV equipped with the ZL - D325 is turning, the differential plays a vital role.It controls the rotational speed of the two drive wheels. As the AGV makes a turn, the inner wheel rotates at a slower speed while the outer wheel rotates faster. This mechanic enables stable and precise steering, similar to how a car's differential allows it to navigate turns in a stable manner.The differential also helps in reducing the friction between the wheels and the ground during turns, which not only extends the lifespan of the wheels but also makes the operation more energy - efficient.Independent Motors for Movement and TurningThe ZL - D325 is designed with independent motors for movement and turning. The motor responsible for forward and backward movement provides the necessary thrust to move the AGV and its load.At the same time, the separate motor for turning controls the rotation of the steering wheel, allowing for highly accurate and responsive steering.This independent motor configuration offers several advantages. Firstly, it simplifies the control system as each motor can be controlled independently, making it easier to program the AGV's movements. Secondly, it provides better power management. For instance, when an AGV needs to make a sharp turn while carrying a heavy load, the turning motor can provide the necessary torque without affecting the forward - moving motor's performance.Low - Friction Wheel SurfaceThe wheel surface of the ZL - D325 is designed to have low friction with the ground. This reduces the energy required to move the AGV, resulting in lower power consumption and longer - lasting batteries (in the case of battery - powered AGVs).Additionally, the low - friction surface minimizes wear and tear on the wheels, reducing maintenance costs. In a logistics center where AGVs are in constant operation, the low - friction wheel surface of the ZL - D325 can significantly improve the overall efficiency of the operation by reducing the frequency of wheel replacements and battery recharges.3. Customization OptionsSpeed CustomizationThe speed of the ZL - D325 can be customized to suit different applications. In some high - speed material - handling scenarios, such as in a fast - paced e - commerce warehouse where goods need to be moved quickly from one location to another, the steering wheel can be adjusted to operate at higher speeds.On the other hand, in applications where precision is more important than speed, like in a precision manufacturing plant where delicate components are being transported, the speed can be set to a lower, more controlled value. This speed customization ensures that the ZL - D325 can be integrated seamlessly into any operation, regardless of its speed requirements.Control Method CustomizationThe ZL - D325 offers two main control methods: automatic navigation and remote control, both of which can be customized. For automatic navigation, the steering wheel can be integrated with various sensors and software systems. In a large - scale automated factory, the ZL - D325 can be programmed to follow a pre - set path using laser navigation or magnetic tape guidance. The sensors on the AGV can detect obstacles in real - time and adjust the path accordingly. In terms of remote control, the system can be customized to use different types of controllers, such as handheld remote controls or wireless joysticks. This allows operators to have precise control over the AGV's movements, which is useful in situations where human intervention is required, such as during initial setup or in emergency situations.4. Industry Significance and Future OutlookThe demand for advanced steering wheels like the ZL - D325 is on the rise, driven by the growth of the AGV industry. The AGV market has been expanding steadily in recent years, with applications in industries such as manufacturing, logistics, and healthcare. In manufacturing, AGVs are used to transport raw materials, work - in - progress components, and finished products, improving production efficiency and reducing labor costs. In logistics, AGVs play a crucial role in warehouses, moving pallets and packages, and optimizing storage space. The healthcare industry is also starting to adopt AGVs for tasks such as transporting medical supplies and equipment. Looking ahead, the future of the AGV and steering wheel industry is bright. Technological advancements such as the development of more powerful and efficient motors, improved sensor technology, and the integration of artificial intelligence and machine learning are expected to drive further innovation. The ZL - D325 is well - positioned to benefit from these trends. For example, as sensor technology improves, the automatic navigation capabilities of the ZL - D325 can be enhanced, allowing for even more precise movement and obstacle avoidance. With the integration of artificial intelligence, the ZL - D325 could potentially learn from its operating environment and adjust its performance in real - time, further improving efficiency and reliability.

2. Innovative Design FeaturesDual - Wheel SurfaceThe dual - wheel surface design of the ZL - D325 is a key feature that enhances its performance. This design distributes the load more evenly, reducing the pressure on each wheel and thus minimizing wear and tear. It also improves the stability of the AGV, ensuring movement even on uneven surfaces. In a warehouse setting, where AGVs need to navigate over various types of flooring, the dual - wheel surface of the ZL - D325 provides the necessary stability to prevent tipping and ensure safe transportation of goods.Equipped with a DifferentialThe inclusion of a differential in the ZL - D325 is another highlight. When an AGV equipped with the ZL - D325 is turning, the differential plays a vital role.It controls the rotational speed of the two drive wheels. As the AGV makes a turn, the inner wheel rotates at a slower speed while the outer wheel rotates faster. This mechanic enables stable and precise steering, similar to how a car's differential allows it to navigate turns in a stable manner.The differential also helps in reducing the friction between the wheels and the ground during turns, which not only extends the lifespan of the wheels but also makes the operation more energy - efficient.Independent Motors for Movement and TurningThe ZL - D325 is designed with independent motors for movement and turning. The motor responsible for forward and backward movement provides the necessary thrust to move the AGV and its load.At the same time, the separate motor for turning controls the rotation of the steering wheel, allowing for highly accurate and responsive steering.This independent motor configuration offers several advantages. Firstly, it simplifies the control system as each motor can be controlled independently, making it easier to program the AGV's movements. Secondly, it provides better power management. For instance, when an AGV needs to make a sharp turn while carrying a heavy load, the turning motor can provide the necessary torque without affecting the forward - moving motor's performance.Low - Friction Wheel SurfaceThe wheel surface of the ZL - D325 is designed to have low friction with the ground. This reduces the energy required to move the AGV, resulting in lower power consumption and longer - lasting batteries (in the case of battery - powered AGVs).Additionally, the low - friction surface minimizes wear and tear on the wheels, reducing maintenance costs. In a logistics center where AGVs are in constant operation, the low - friction wheel surface of the ZL - D325 can significantly improve the overall efficiency of the operation by reducing the frequency of wheel replacements and battery recharges.3. Customization OptionsSpeed CustomizationThe speed of the ZL - D325 can be customized to suit different applications. In some high - speed material - handling scenarios, such as in a fast - paced e - commerce warehouse where goods need to be moved quickly from one location to another, the steering wheel can be adjusted to operate at higher speeds.On the other hand, in applications where precision is more important than speed, like in a precision manufacturing plant where delicate components are being transported, the speed can be set to a lower, more controlled value. This speed customization ensures that the ZL - D325 can be integrated seamlessly into any operation, regardless of its speed requirements.Control Method CustomizationThe ZL - D325 offers two main control methods: automatic navigation and remote control, both of which can be customized. For automatic navigation, the steering wheel can be integrated with various sensors and software systems. In a large - scale automated factory, the ZL - D325 can be programmed to follow a pre - set path using laser navigation or magnetic tape guidance. The sensors on the AGV can detect obstacles in real - time and adjust the path accordingly. In terms of remote control, the system can be customized to use different types of controllers, such as handheld remote controls or wireless joysticks. This allows operators to have precise control over the AGV's movements, which is useful in situations where human intervention is required, such as during initial setup or in emergency situations.4. Industry Significance and Future OutlookThe demand for advanced steering wheels like the ZL - D325 is on the rise, driven by the growth of the AGV industry. The AGV market has been expanding steadily in recent years, with applications in industries such as manufacturing, logistics, and healthcare. In manufacturing, AGVs are used to transport raw materials, work - in - progress components, and finished products, improving production efficiency and reducing labor costs. In logistics, AGVs play a crucial role in warehouses, moving pallets and packages, and optimizing storage space. The healthcare industry is also starting to adopt AGVs for tasks such as transporting medical supplies and equipment. Looking ahead, the future of the AGV and steering wheel industry is bright. Technological advancements such as the development of more powerful and efficient motors, improved sensor technology, and the integration of artificial intelligence and machine learning are expected to drive further innovation. The ZL - D325 is well - positioned to benefit from these trends. For example, as sensor technology improves, the automatic navigation capabilities of the ZL - D325 can be enhanced, allowing for even more precise movement and obstacle avoidance. With the integration of artificial intelligence, the ZL - D325 could potentially learn from its operating environment and adjust its performance in real - time, further improving efficiency and reliability.5. Application Scenarios

Logistics and WarehousingIn logistics and warehousing, the ZL - D325 is a valuable asset. In a large distribution center, AGVs equipped with ZL - D325 steering wheels can move pallets of goods from the receiving area to storage locations and then to the shipping area. The ability to customize the speed and control method of the ZL - D325 makes it suitable for different warehouse layouts and operational requirements. For example, in a narrow - aisle warehouse, the AGV can be programmed to move slowly and precisely, while in a large, open - space warehouse, it can operate at higher speeds to increase throughput.Manufacturing IndustryIn the manufacturing industry, the ZL - D325 can be used in various production lines. In a large - scale electronics manufacturing plant, AGVs with ZL - D325 steering wheels can transport circuit boards, components, and finished products between different workstations. The high load - bearing capacity of the ZL - D325 allows it to handle heavy trays of components, while the precise steering and low - friction wheel surface ensure movement on the factory floor. This not only speeds up the production process but also reduces the risk of damage to the delicate electronic components.Healthcare FacilitiesEven in healthcare facilities, the ZL - D325 can find applications. AGVs with these steering wheels can be used to transport medical supplies, medications, and even laboratory samples within a hospital. The stable movement of the ZL - D325 is important in a healthcare setting, as it reduces the risk of spills or damage to sensitive medical materials. The automatic navigation feature can be customized to ensure that the AGV can navigate through busy hospital corridors, avoiding patients and staff while delivering essential supplies in a timely manner.In conclusion, the ZL - D325 differential drive steering wheel is a versatile, high - performance product that offers a wide range of benefits. Its exceptional load - bearing capacity, innovative design features, customization options, and relevance to various industries make it a top choice for anyone looking to enhance their material - handling operations. Whether you are in manufacturing, logistics, or healthcare, the ZL - D325 can be tailored to meet your specific needs and help you achieve greater efficiency and productivity.

Related products

undefined

Products Message

Products

Guangzhou Wisdom Wheel Science Technology Ltd.

No. 1436, Guangcong 9th Road, Guangzhou, Guangdong, China

Whatsapp/MB: Kelly +86-+852-81642329

Jackson +8615012435018

Candy:+86 +852-51645933

CopyRight © 2024 Guangzhou Wisdom Wheel Science Technology Ltd.

Powered by www.300.cn SEO Tags En_CityProduct